Have ever heard about laser etching head technology? It is an interesting concept shaping up the manufacturing world to will enhance your speed, efficiency and accuracy in much increases proportion as compared to conventional techniques so far.

A laser etching head is a specialized tool that uses an almost inelastic light beam (laser) to precisely mark patterns or logos on plastic, metal or glass. This is done by vaporizing the surface of material, so a pressure mark can not remove it from durability side.

Our laser etching technology has been around for a while, but improvements keep making it faster and more accurate than ever before. However, now this technology can output immensely intricate designs that could not be produced using conventional engraving techniques.

If you are using any of the traditional methods for marking and engraving your product at present than this laser etching head technology is going to save a lot on time, cost over that.

A Laser Etching Head can produce a permanent, durable mark that meets the most stringent requirements for fade-, scratch- and damage-resistance throughout manufacture and product life. Laser etching heads also has the ability to produce extremely fine designs meaning very delicate and intricate logos or even patterns that simply would not have been practical with laser engraving.

Within the manufacturing industry, laser etching head technology is quickly becoming the norm for marking and engraving. And with further advancements in this technology, the prospects of applications and uses for laser etching heads can only grow.

This trend towards laser etching will likely drive further adoption of when it comes to unique design, branding and patterning by manufacturers in the future.

Ready to change the way you manufacture?? Adding in laser etching heads to your production line is a simple, all-encompassing way of upgrading both the performance and quality.

The heads for laser etching are available from many manufacturers at a varying range of prices, which ensures there is an option relevant to all sizes of business.

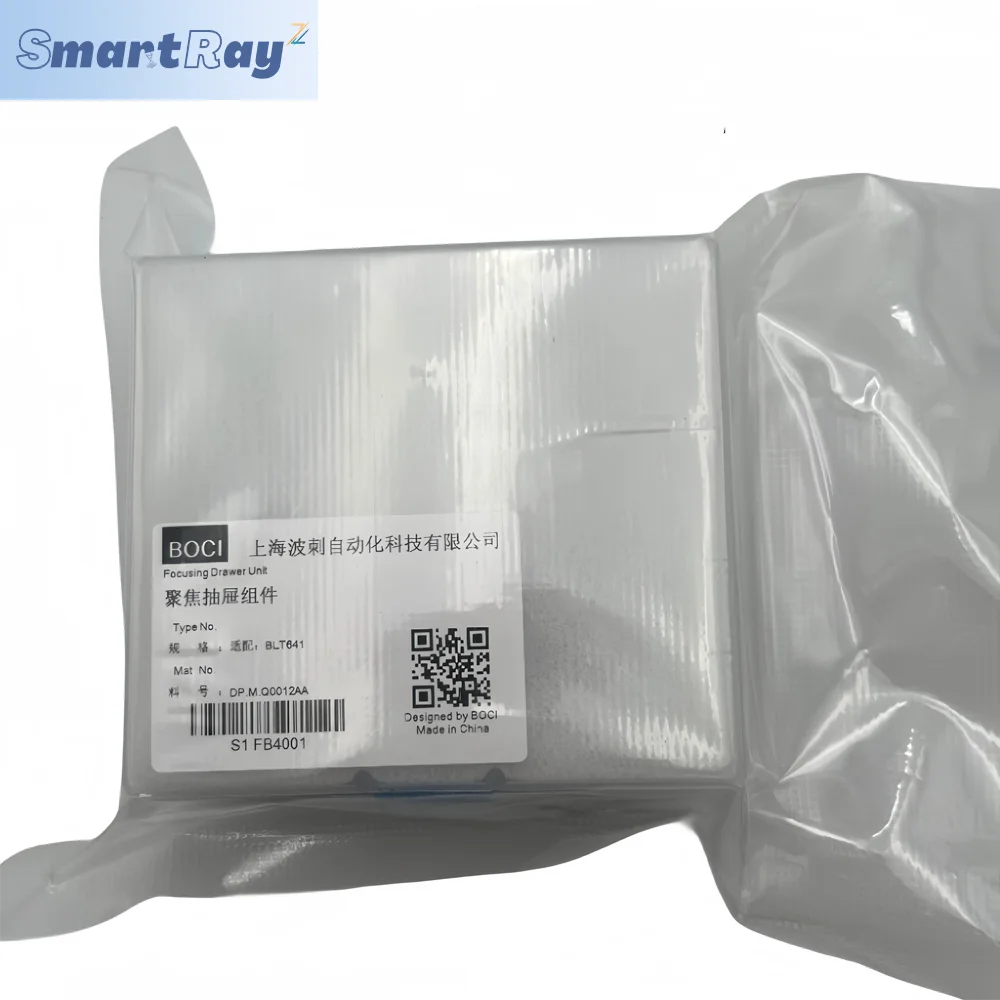

Aside from the laser etching heads themselves many manufacturers also provide ancillary solutions to ensure the smooth implementation of this technology. At the same time, a number of companies present such tools like software that could be potentiated with laser etching heads in order to deliver custom-made images as well they offer sub-systems (cooling devices and shields) which would shield their machines from overheating or damages.

You can make your production line more time-effective and productive by laser etching heads, combined with compatible accessories to optimise the manufacturing process.

To sum up, it can be said that laser etching head technology is a revolutionary innovation aimed towards the manufacturing sphere. With laser etching heads, you have the ability to create intricate designs that are permanent, durable against damage, and extremely fast both in creation turnaround time. Whether you want to streamline your production levels or simply add custom designs to your goods, designer laser etching head technology is the best fitting solution for it.

Our experts decades experience the industry and committed offering expert advice support. From selection products laser etching head, assistance installation troubleshooting, we here assist in every step.

We your complete laser factory. We offer a variety items that will satisfy your requirements. We stock all laser parts such as laser etching headheads and laser sources, chillers, and laser welding equipment you require to enhance the performance of lasers.

We know every project unique, laser etching head flexible approach permits to provide customized options. Our skilled team work closely you ensure specification is tailored to meet your specific requirements.

Our drive to be the best drives us to produce laser-cut products that are of the highest quality. Each item tested thoroughly and is manufactured strict guidelines, ensuring longevity and reliability. You rely on our products to ensure the safety and effectiveness of your operation.