SmartRay Laser Technology Co.Ltd.

The Max Laser Power 1500W 2000W 3000W 6000W Laser Cutting Welding Machine Max Fiber Laser Source from SmartRay Laser may be the solution ideal industrial-scale laser cutting and welding needs. With numerous energy solutions often, the you can be plumped for by you that most useful suits the requirements you have got.

This laser device and cutting welding built with state-of-the-art technology enabling for high-precision cutting and welding of several materials like metal aluminum copper and metal. The SmartRay Max 1500W 2000W 3000W 6000W Laser Cutting Welding Machine Max Fiber Laser supply is fairly efficient providing cutting maximum welding speeds with minimal power usage.

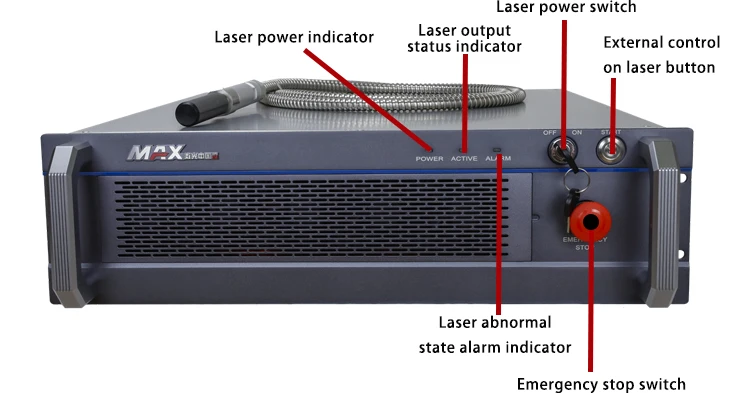

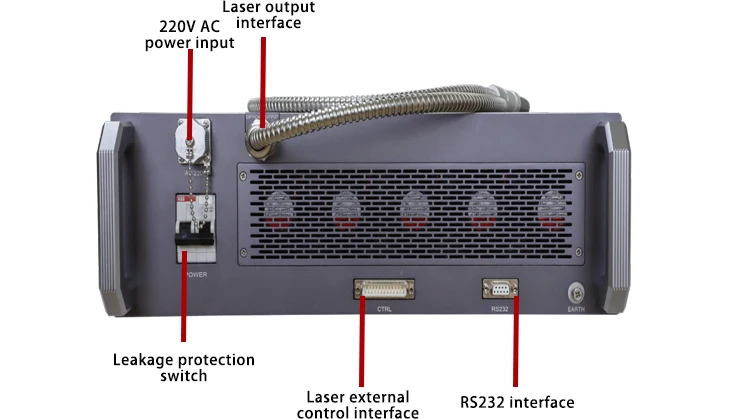

SmartRay Laser's SmartRay Max Laser Power 1500W 2000W 3000W 6000W Laser Cutting Welding Machine Max Fiber Laser supply is sold with advanced features which can make it the choice ideal different applications. It offers beam superior stable performance and a lifespan extended. The gear includes an application user-friendly making it an easy task to run for inexperienced users.

The SmartRay Laser Technology Co.Ltd. Max Laser Power 1500W 2000W 3000W 6000W Laser Cutting Welding Machine Max Fiber Laser supply from SmartRay Laser features a processor powerful allows for precision cutting and welding on intricate designs. It is possible to create your customized designs making utilization of 2D and 3D software pc is modeling and in addition the product will replicate them flawlessly. Additionally, the unit can seamlessly switch between cutting and modes welding making it a solution all-in-one your metalworking requirements.

The SmartRay Max Laser Power 1500W 2000W 3000W 6000W Laser Cutting Welding Machine Max Fiber Laser supply from SmartRay Laser additionally boasts fast cutting and rates welding that allows one to work faster without compromising precision. This product is fantastic for different companies including automotive aerospace shipbuilding and construction.

|

Power

|

1500W

|

|

Working mode

|

Continuous/pulse

|

|

State of polarization

|

random

|

|

Power regulation range (%)

|

10~100

|

|

Center wavelength (nm)

|

1080(±10)

|

|

Spectral bandwidth 3d (nm)

|

3~5

|

|

Short-time power stability (%)

|

±1

|

|

Long-term power stability (%)

|

±2

|

|

Laser on time (us)

|

50~80

|

|

Laser off time (us)

|

30~50

|

|

Modulation frequency (KHz)

|

20~50

|

|

Indicated red light power (PW)

|

150

|

|

Output mode

|

Standard QBH (LOC)

|

|

Length of optical fiber cable (m)

|

15

|

|

Working voltage (VAC)

|

220

|

|

Rated power consumption (KW)

|

6

|

|

Operating ambient temperature (%)

|

10~40

|

|

Storage temperature (℃)

|

-10~60

|

|

Relative humidity of working environment

|

10~85

|

|

Cooling mode

|

hydrocooling

|

|

Operating Weight (kg)

|

68(±3)

|