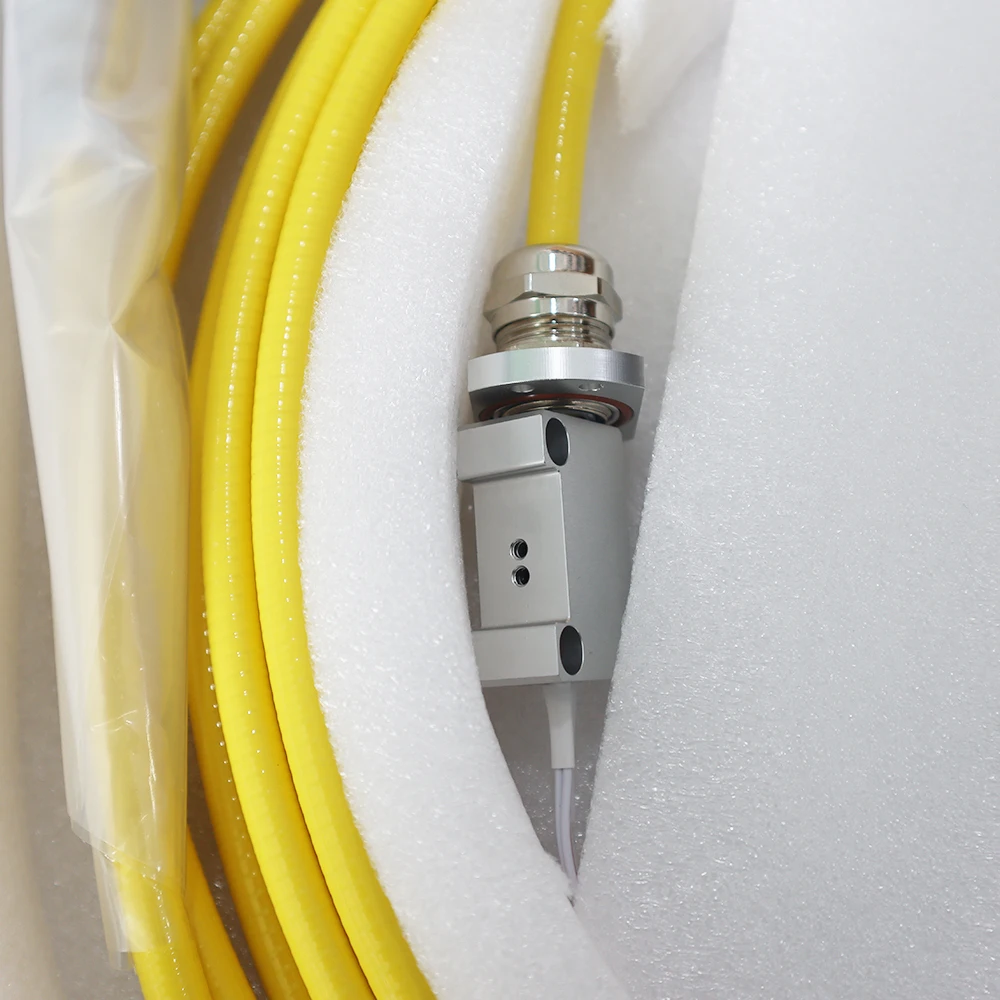

Haben Sie sich je gefragt, wie Maschinen so mühelos durch solch widerstandsfähige Materialien schneiden können? Das mag wie Magie erscheinen, aber in Wirklichkeit gibt es eine wissenschaftliche Erklärung dafür. Eine Linse ist eines der Hauptbestandteile, die bei diesem Verfahren, dem Laserschneiden, verwendet wird. Der Laser – Laser ist die Abkürzung für Light Amplification by Stimulated Emission of Radiation – ein fokussierter und gerichteter Hochenergie-Strahl, der durch Holz, Plexiglas und Stahl schneidet, als wären sie heiße Butter; aber dieser laseroptik war kein gewöhnliches Werkzeug – der vorkantige Schnitt zu einer eingestellten Lasereinheit – denn es half dabei, die Strahlen direkt auf das Zielmaterial für die Verarbeitung zu fokussieren. Und das ist das spezielle Werkzeug, das ihnen eine so einzigartige Fähigkeit verleiht, ihre Arbeit so gut und auch zeitlich sehr effizient auszuführen. BILLIGE OEM SCHNITT-LASERLINSE Diese Linse unterstützt die Konzentration des Laserstrahls und hilft dabei, einen guten, robusten Schnitt mit hoher Effizienz zu erzielen. Die Schneidlasereinheit muss dann diesen Strahl fokussieren und ihn auf eine bestimmte Stelle des Materials richten. Der Laser schmilzt dieses Material – und in manchen Fällen verdampft es es sogar – an diesen Punkten. Diese Methode führt zu einer ordentlichen, klaren Kante, die sofort weiterverwendet werden kann. Diese Lasereinheit führt zu sehr genauen Schnitten bei einer Vielzahl von Projekten.

Schneide Laserlinsen, die aus Glas, Quarz oder Silizium hergestellt werden. Diese Materialien werden aufgrund des Tunnelns der extrem hohen Energie von Laserstrahlen ausgewählt. Wir sind Zhilei Laser, die Linsen, die von unserer Firma hergestellt werden, verwenden nur hochwertige Materialien, um zu garantieren, dass Sie nur das Beste bekommen. Diese Linsen sind in verschiedenen Größen, Formen und Dicken verfügbar, um laserlinse Fokussierung den individuellen Anforderungen verschiedener Maschinen gerecht zu werden. Dies ist wichtig, da unterschiedliche Schneidungsanwendungen eine bestimmte Form von Linse benötigen, um die Arbeit richtig auszuführen. Laserlinsen sind integraler Bestandteil der Funktionalität einer Laserschneidanlage, da sie es ermöglichen, viele verschiedene Arten von Materialien zu schneiden. Dies kann eine breite Palette von Materialien umfassen – Metalle wie Stahl und Aluminium, Plastik, Laminate (auf Holz), Leder oder Stoffbespannungen. Eine Laserschneidanlage kann durch den Einsatz verschiedener Linsentypen unterschiedliche Materialstärken schneiden. Diese breite Palette an Anwendungen ist einer der Gründe, warum so viele Industrien auf Laserbearbeitung setzen.

Mit dem richtigen Upgrade der Laserschneidelinse kann Ihre Laserschneidtechnik stärker als je zuvor werden. Wenn es darum geht, von einer Markierungs-Laserschneidelinse zu einer Schneidelinse überzugehen, gibt es viele Vorteile. Langlebige Laserschneidelinse: Eine langlebige, schneidende Laserschneidelinse bietet sauberere Schnitte, stärkere Kanten und schnellere Schneidgeiten. laser-Schutzbrille ist ein echter Segen, besonders für Unternehmen, da sie so ihre Ressourcen sparen, zusätzlich zu exzellenten Ergebnissen. Wenn es um den Verkauf von Dingen geht, wie bei allem in der Fertigung, macht Effizienz und die Erstellung hochwertiger Produkte den Unterschied.

Ein weiterer Vorteil von Laserschneidelinsen ist, dass Sie eine hochpräzise Schneidung ganz einfach durchführen können. Durch die Reduzierung der Menge des Laserstrahls und die Steigerung seiner Leistung bietet es mehr Unterstützung zur Reduktion der Schneidzeit. Dadurch können Sie komplexere Schneidarbeiten ausführen und komplexe Formen und Designs auf nichtleitenden Materialien erzeugen. schutzlaser schnittwillige Leichtigkeit beim Schneiden. Egal, ob Sie an kleinen Teilen oder großen Designs arbeiten, die Schneidelinsen können helfen, Ihr Ziel zu erreichen. Click To Tweet

Laserschneidelinsen sind eine großartige Wahl, da sie viele Vorteile bieten. Nachhaltig, widerstandsfähig und natürlich müssen Sie sie auch nicht oft wechseln. Das bedeutet nicht nur Geldsparen, sondern reduziert auch Unterbrechungen in Ihren Schneidvorgängen. Laserschneidelinsen ermöglichen es, glatte und genaue Schnitte zu erstellen, was preise für optische Linsen wiederum die Nachbearbeitungszeit erheblich verkürzen kann. Und das macht sie zu einer hervorragenden Option für den kommerziellen und industriellen Fertigungsbetrieb.

Wir sind Ihre komplette Laserfabrik. Wir bieten eine Vielzahl von Artikeln, die Ihre Anforderungen erfüllen. Wir führen alle Laserersatzteile wie Schneidlaser-Optikköpfe und Laserquellen, Kühlanlagen sowie Ausrüstung für das Laserschweißen, die Sie benötigen, um die Leistung Ihrer Laser zu verbessern.

Mit jahrelanger Erfahrung im Bereich Schneidlaser-Optik ist unser Team von Experten bestrebt, Ihnen fachkundigen Rat und Unterstützung zu bieten. Wir stehen Ihnen zur Seite, von der Produktauswahl bis hin zu technischer Unterstützung, Installationshinweisen und Fehlerbehebung.

Unser Anspruch, die Besten zu sein, treibt uns dazu an, Schneidlaser-Optik und Laserprodukte von höchster Qualität anzubieten. Jedes Produkt durchläuft strenge Prüfungen und wird gemäß strenger Spezifikationen hergestellt. Dies gewährleistet zuverlässige und langlebige Leistung. Seien Sie unbesorgt – Sie können sich auf erstklassige Produkte für einen effektiven und sicheren Betrieb verlassen.

Wir, dass jedes Projekt anders ist, weshalb ein flexibler Ansatz es ermöglicht, angepasste Optionen bereitzustellen. Benötigen Sie spezifische Abmessungen, Materialien, Laserschnitt-Len-Design-Anpassungen, arbeitet das sachkundige Team mit Ihnen zusammen, um die Spezifikation an Ihre speziellen Anforderungen anzupassen, damit diese perfekt auf Ihre Bedürfnisse zugeschnitten ist.