Fiber laser cutting nozzle is the key factor to control precision of high-speed cutting. These nozzles' accuracy could be thrown off by any variety of factors, all of which would result in an inferior finished product. In order to enhance the accuracy of fiber laser nozzles for wholesale, we should pay more attention to the cutting level in all respects. By learning about these factors and employing appropriate techniques, wholesale buyers can optimize the performance of their fiber laser cutting machines.

How to make the accuracy of the nozzle of fiber laser become better when it react in wholesale?

The precision of the fiber laser nozzle is also related to the quality of the nozzle itself. You need to invest in premium fiber laser nozzles that are made for high speed cutting. Wholesale buyers can bet on a long and accurate cutting process by opting for reliable, durable nozzles. Routine, systematic maintenance and cleaning of the laser machine in order to prevent blockage and uphold high performance cutting are also required. By adopting these maintenance techniques, wholesale buyers can extend the life of their fiber laser nozzles while also reducing potential for errors or imprecision during cutting services.

Where you can Get premium fibre laser nozzles for high speed cutting:

For businesses needing top-rated fiber laser consumables for high speed cutting, using a reliable supplier like Zhilei Laser is of paramount importance. Zhilei Laser is not only dedicated to high-quality cutting solutions for industrial manufacturing, it also provides machine serving of the highest caliber standpoint. With years of experience, Zhilei Laser provide different types of fiber Laser nozzles for high-speed cutting use. Collaborating with Zhilei Laser, trade purchasers are able to avail themselves to latest innovative technology and stable competitive products by taking their unique demands into consideration. What’s more, Zhilei Laser professional team can advise and assist wholesale customers to optimize their cutting machines and help the buyers to make their fiber laser nozzle correct. Wholesale buyers can rest easy in the knowledge that by making Zhilei Laser their supplier, they will always have access to best-in-class fiber laser nozzles which provide unparalleled performance and accuracy for their cutting tasks.

Information of fiber laser nozzles precision you should know leaves-pattern

The spraying speed is reasonable and the effect is very good, so that to reduce unnecessary waste.

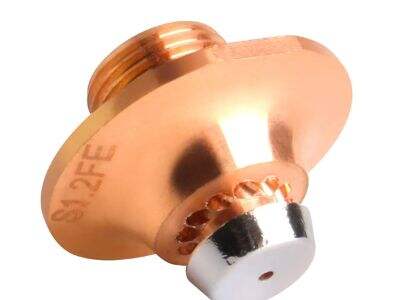

Fiber laser cutting nozzles are a key part for high speed cutting. They direct the laser beam precisely at the workpiece to be cut. The accuracy of fiber laser cutting head is very important for cutting workpieces accurately and cleanly. Nozzle design, material quality and durability all affect the accuracy of a fiber laser cutting nozzle.

The nozzle structure significantly affects the cutting accuracy of fiber laser. The nozzle geometry and dimensions can affect the focus, and intensity of the laser beam. It’s critical that the right nozzle design is selected for the cutting application at hand to maximize productivity. It also seems the quality of material used for the Laser nozzle makes a difference on longevity too. The higher quality material can bear the heat and pressure of cutting with the laser and as a result, it produces more consistent and accurate cuts.

Regular maintenance is also very important to keeping the fiber laser nozzles in precision. Periodically removing the nozzle can help prevent debris and ensure consistent alignment. Checking the nozzle for damage and replacing as needed may help prevent misalignment or poor performance. Looking after the nozzle and ensuring it is in a good condition can help enhance the accuracy of your cutting applications and prolong life of equipment.

How to get best performance of fiber laser nozzles in high speed cutting:

Several important steps should be followed to achieve the best cutting performance of fiber laser nozzles in high speed cutting applications. First, it is important that an appropriate type of nozzle is chosen for the selected cutting use. Various materials and thicknesses need different nozzles to make perfect joints they can be used. Nozzle design, material quality and compatibility with the laser cutting machine should all be taken into consideration.

Secondly, it is the necessity to take care of your nozzle in order for good quality working. Maintaining the head by cleaning the sensors can help to alleviate problems such as blockages or offsets. It is also crucial to change the nozzle when it becomes worn, so as not to compromise cutting preciseness. Also, changing nozzle settings depending on the material being cut and the desired cutting speed can contribute to efficiency and accuracy.

Questions to ask when buying bulk fiber laser nozzles:

Before you buy Fiber Laser nozzles in bulk, here are a few key questions to ask so that you know that you are getting the best quality and value for your money. The first question you should ask is about the quality of the nozzles in material. Materials of the best type survive the high temperature and pressure of the laser beam, making cuts more accurate and constant. If possible, inquire about how the nozzles are manufactured, and what quality control measures are in place to ensure reliability and longevity.

Second, remember to inquire whether the nozzles are compatible with your laser cutting machines. Making sure the nozzles are compatible with your machine can help avoid compatibility issues and allow for optimum performance. Also asking about warranty and what after sales support is available you a customer will also be given peace of mind that there is help available should problems occur. By asking such questions and getting the right answers, you will be able to buy fiber laser nozzles in bulk wisely.

Table of Contents

- How to make the accuracy of the nozzle of fiber laser become better when it react in wholesale?

- Where you can Get premium fibre laser nozzles for high speed cutting:

- Information of fiber laser nozzles precision you should know leaves-pattern

- How to get best performance of fiber laser nozzles in high speed cutting:

- Questions to ask when buying bulk fiber laser nozzles:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BN

BN

LO

LO

LA

LA

MY

MY

UZ

UZ