Zhilei laser is a company dedicated to offering various choices for industrial thermal application solutions, committed on enhancing the welding/cutting efficiency with Fiber Laser Nozzle. Our company Shanghai SmartRay Laser Technology Co., Ltd provide laser accessories / spare parts and cutting machines variety of products selected as our global fabricator customers require. with a dedication to providing tailored products and quick delivery, our goal is to create long-term relationships with your customized needs. there will be times on welding & cutting production that fiber laser nozzle could increase the efficiency, accuracy of process, improve quality and be able to provide cost-effective solutions for an operation

How Fiber Laser Nozzles Can Improve Welding Efficiency

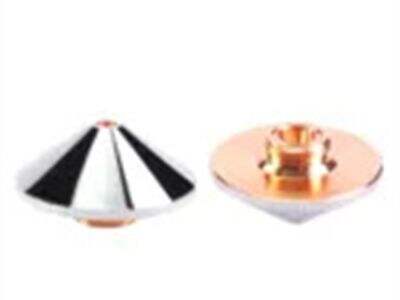

Fiber laser nozzles are mounted to enhance the efficiency of welding process by stabilizing and concentrating the laser beam during welding. These nozzles aid in regulating the distribution of heat and spatter residues, keeping your welds clean, and allowing them to be more accurate. Fiber laser nozzles with the laser beam delivery optimized enable fabricators to weld faster and minimize downtime. Moreover, the shape and the material used for the nozzles itself are programmed to provide better cooling and longer life – offering a cheap solution when it comes to efficiency welding

Optimally Cutting Precise by Using a Fiber Laser Nozzle

In cutting scenarios, fiber laser nozzles are invaluable for increasing precision, and attaining crisp, flawless cuts in materials. These nozzles are engineered to deliver a high-performance beam focused at the cutting front with optimal shape and intensity, resulting in accurate cuts with reduced kerf width and heat-affected zones. Through fine-tuning cutting parameters and directing laser energy efficiently to the workpiece, fabricators can create intricate patterns and clean finishes on metal sheets, tubes or other items. Fiber laser nozzles also help to reduce material waste and advance cutting effi- ciency, all of which can save time and money for job shops

Advancing Productivity With Fiber Laser Nozzles

Increasing the efficiency and accuracy of welding and cutting processes help fiber laser nozzles to support fabricators productivity improvements across the board. Faster welding speeds along with reduced set up times and greater cutting accuracy enable manufacturers to produce more parts in less time, at fast turn-around rates because of tight deadlines and customer requirements. Reliable and durable fiber laser nozzles to last for long time, constantly provide stable cutting performance reducing machine maintenance cost. This leads to more production, better workflows and ultimately increased profitability for industrial manufacturers

Improving the Quality and Uniformity of Welds with Fiber Laser Nozzles

Quality-control is important in welding to satisfy structural demands and product reliability. The Fiber laser nozzles provide quality and consistency in welding while delivering a stable, focused laser beam that forms clean and strong welds. Providing consistent welding performance, the control and accuracy achieved with these nozzles translates into minimal spatter, minimum distortion and optimal joint penetration - quality credentials that can help add a new level of respectability to your welding. In laser welding, fabricators can count on fiber laser nozzles for consistent results that minimize rework and scrap rates yet offer excellent weld quality within a variety of applications

Affordable Answers to Welding and Cutting Applications using Fiber Laser Nozzles

Not only do fiber laser nozzles increase efficiency, accuracy, production and quality; but they also provide cost effective solutions for welding and cutting applications. These nozzles provide laser beam delivery optimization, and heat input minimization to cut overall operating costs and wasted materials as well. Fabricators can realize extended nozzle life, reduced maintenance and increased part output which translates to substantial savings when calculated over time. Fiber laser nozzles Features and advantages: Zhilei Laser's Fiber Laser nozzles, with high quality & competitive prices, are designed to give business a powerful cutting solution with value for money benefit in mind that helps businesses get the maximum performance and long life from there consumables

Fiber laser Nozzle is designed to improve the cutting and welding capabilities, higher processing efficiency, more stability and cost effective solution, are widely used in Industrial production. About From the beginning, we have been dedicated to providing small and medium-sized enterprises with high-quality metal marking and cutting systems To help people meet their production needs in order that all can participate productively at any time anywhere. With a focus on custom design capabilities, and competitive delivery times for our customers around the world. Researching development customer satisfaction is our dutyWe are commited to equip chinese latest technology laser machines making more businesses grow up in the world. No matter what kind of price reasonable products we all offeredThe same ioffered professional total solutions choices If this sounds like something you would en like infoContact us today to learn more. Whether you wish to improve the quality of welding, provide higher precision cutting or improve productivity generally, fiber laser nozzles from Zhilei Laser have become an absolute necessity in achieving excellent finish results for your welding and cutting needs

Table of Contents

- How Fiber Laser Nozzles Can Improve Welding Efficiency

- Optimally Cutting Precise by Using a Fiber Laser Nozzle

- Advancing Productivity With Fiber Laser Nozzles

- Improving the Quality and Uniformity of Welds with Fiber Laser Nozzles

- Affordable Answers to Welding and Cutting Applications using Fiber Laser Nozzles

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BN

BN

LO

LO

LA

LA

MY

MY

UZ

UZ