Fiber laser technology has literally revolutionized the industry, giving a more sophisticated and efficient way to cut through different materials like metals as well as plastics even wood. The nozzle - cambit the component that shapes and directs the laser beam to deliver a clean, burr-free cut with high speed-is critical in this innovative cutting approach.

Fiber laser nozzles have a wide range of funtions which are essential for the fiber laser cutting. More often they are used to focus the laser beam, creating an intense high energy cutting ray that can slice through crystalline and reflective materials with ease. Operators can fine-tune the laser beam even more to their exact cutting needs by making adjustments in shape, size and nozzle design.

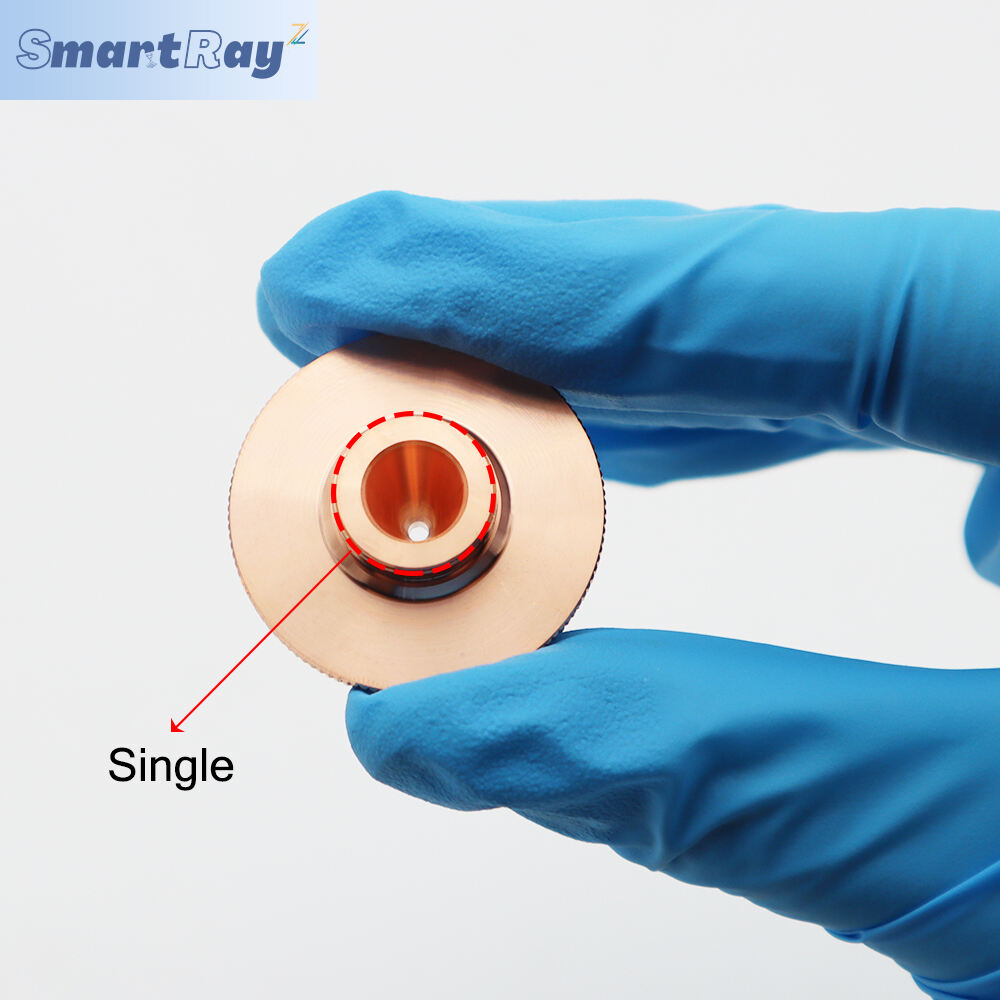

Fiber laser nozzles are available in multiple types, each presenting advantages and benefits for different cutting applications. This gives greater control and accuracy, an example of this can be a focusing nozzle for cutting thin materials where as defocusing will not help you in achieving any additional focus rather the speed increases instead. Likewise, A conical nozzle provides a cleaner cut finish where trumpet nozzles are towards thicker materials.

In addition to providing shape of the laser beam, fiber Laser nozzles are also important for controlling cutting. The nozzles surround the area where gas is being shot, guiding it around the path of laser beam to create a protective cone and prevent heat damage or oxidation on material. The gas flow also helps make sure unwanted material is cleared from the laser beam path, leading to a more consistent cutting quality.

Enabling this type of cutting performance and results is best done by investing into high-quality fiber laser nozzles. Quality-crafted nozzles Improve your cutting more effectively and precisely which then cut faster, accurately delivered attributes for reduce the cost in manufacturing process.

Correct selection of fiber laser nozzle depends on what material the nozzles cut, size thicknesses it cuts to; along with which bolt type (diameter and thread pattern) used around each specific brand of laser cutting machine. Working with laser cutting professionals who have the depth and breadth of experience to help you pick a nozzle that is right for your application ensures the best possible results.

Fiber laser nozzles can also be used in far more original ways than purely for industrial cutting processes, They have a much wider range of uses even in other sectors where manufacturing is concerned. For example, laser surface treatment and marking processes require very well focusable beams that are adjusted to the specific demands of a job. This not only makes the fiber laser nozzles necessary but dictates They provide a means for how we shape and focus our beam to achieve a desired result.

Fiber laser nozzles are necessary elements of any industrial process used for cutting, marking or when a surface treatment is required. By choosing the right nozzle for the application and using it correctly, laser cutting operators can achieve precision cool-cutting that meets even the most demanding manufacturing requirements.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BN

BN

LO

LO

LA

LA

MY

MY

UZ

UZ