Правилното подравняване на дюзата е важно за добрия резултат от лазерното заваряване. Ако дюзите не са правилно подравнени, лазерният лъч може да пропусне целта си и да създаде лоши заварки. Това може да доведе до крехки съединения, които не издържат добре на натиск. А ако дюзите не са правилно подравнени, може да се появят допълнителни пръски и пръски - дори вредни за околното оборудване, да не говорим за мръсотията по ръцете ви. При лазерното заваряване центрирането на дюзите е пряко повлияно от точността и чистотата на заваръчните шевове.

Защо точно центриране на дюзите е важно за високо качество при лазерно заваряване

Правилното подравняване на дюзите е ключово за по-високо качество при лазерно заваряване , каза компанията. Ако дюзите са точно индексирани, лазерният лъч може да бъде прецизно фокусиран в зоната за заваряване, което осигурява силни и последователни шевове. Този степен на точност е от решаващо значение, особено в индустрии, където качеството на заварката е от първостепенно значение за безопасността и производителността – като автомобилната, аерокосмическата и производството на медицински устройства. Ако не са точно позиционирани, могат да възникнат слаби заварки, които биха могли да нарушият цялостната устойчивост на крайния продукт. Чрез прецизна подредба на дюзите Zhilei Laser може да осигури повтарящи се, надеждни заварки с най-високо качество и производителност

Нови подходи за подобряване на ефективността в приложения за лазерно заваряване чрез правилната ориентация на дюзата

Правилното подравняване на дюзата не е важно само от гледна точка на качеството, но също така може значително да повиши производителността в приложенията за лазерно заваряване. Правилното подравняване на дюзата позволява на лазерния лъч да функционира по-ефективно, намалявайки преработката и увеличавайки производителността. Това представяне е изключително важно по отношение на времевите ограничения за производството и икономиката. С помощта на точни инструменти и техники за подравняване процесът на лазерно заваряване на Zhilei може значително да се опрости, спестявайки време и пари, като същевременно се поддържа най-високото качество. В крайна сметка нашата компания поставя правилното подравняване на дюзата на първо място, за да предложи висококачествени и ефективни решения за лазерно заваряване на цена, която можете да си позволите

В контекста на Лазерно заваряване , точно подравняване на дюзата е важно за получаване на висококачествени и прецизни заваръчни съединения. В Zhilei Laser знаем, че получавате това, за което плащате, когато става въпрос за закупуване на оборудване, което осигурява най-добри резултати при монтирането на дюзи и лазерно заваряване

Ето основните предимства от инвестиране в прецизно подравняване на дюзи за лазерно заваряване

Прецизното подравняване на дюзата е важно лазерният лъч да удря точно в определена позиция върху детайла, което води до здрав и равномерен заваръчен шев. Чрез точното позициониране производителите могат да намалят риска от порестост, пукнатини и деформации в заварката. Освен това правилното подравняване допринася и за по-лесна и бърза работа, като се минимизира необходимостта от преработка, което подобрява крайното качество на заварката

Къде да набавите висококачествено оборудване, което осигурява перфектно подравняване на дюзи при лазерно заваряване

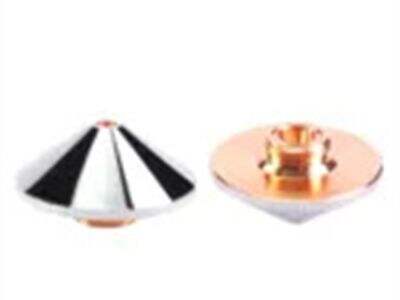

В Zhilei Laser предоставяме висококачествени машини за лазерно заваряване, произведени без огледало на накрайника. С нашата напреднала технология и прецизна изработка създадохме серия продукти, които осигуряват последователно точни резултати – така производителите могат да постигнат заварки от по-високо качество с по-малко отпадъци. Независимо дали имате нужда от системи за лазерно заваряване, накрайници или инструменти за подравняване – с Zhilei Laser ще намерите правилните решения за подобряване на вашите процеси на заваряване

Типични проблеми и решения при подравняването на накрайника при лазерно заваряване

Често срещан проблем при лазерното заваряване е контролът върху позицията на накрайника, особено при сложни геометрии или листови материали. За избягване на тези проблеми лазерно заваряване системите трябва да бъдат оборудвани с усъвършенствани опции за подравняване, които позволяват автоматична корекция на позицията на накрайника по време на производството (в реално време). Освен това, периодично обслужване и калибриране на устройството могат да помогнат за запазване на правилното подравняване на накрайника с течение на времето

Точното положение на дюзата е от голямо значение за постигане на най-добри резултати при лазерно заваряване. Като закупуват висококачествено оборудване и прилагат допълнителни решения за компенсиране на проблемите с подравняването, производителите могат значително да подобрят практиките си при заваряване и да оптимизират качеството на заварката. Zhilei Laser проектира и предлага иновативни продукти с мисията да помогне на клиентите си да постигнат успех в своите заваръчни приложения

Съдържание

- Защо точно центриране на дюзите е важно за високо качество при лазерно заваряване

- Нови подходи за подобряване на ефективността в приложения за лазерно заваряване чрез правилната ориентация на дюзата

- Ето основните предимства от инвестиране в прецизно подравняване на дюзи за лазерно заваряване

- Къде да набавите висококачествено оборудване, което осигурява перфектно подравняване на дюзи при лазерно заваряване

- Типични проблеми и решения при подравняването на накрайника при лазерно заваряване

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

BN

BN

LO

LO

LA

LA

MY

MY

UZ

UZ