The laser sealing rings are a little bit like magic rings that hold things closed tight. Today we are going to learn about everything Laser chiller, how they work, and why they are so special!

Zhilei Laser, Laser sealing rings have a number of special benefits that impart uniqueness. So the first thing is they are quite strong and can take a lot of pressure. This allows them to maintain a tight seal even with quite a bit of pressure trying to open them. Until now, you were handling a bottle with a hard-to-open seal. Part of laser sealing rings is its high-fit, so no detection can oozing. This matters a lot because leaks can lead to serious problems. However, these rings are extremely long-lasting, which means you won't have to change them for a long time. They are built to last and can continue running smoothly for years despite hard conditions.

What is learned refers to the laser technology that makes laser sealing rings so wonderful and powerful. A Zhilei Laser, laser beam is a super strong beam of light, capable of doing many things normal light simply cannot. While the sealing rings the laser perform an extremely strong and tight seal around whatever they seal. Using a laser that can slice material with extreme precision, the seal is the perfect shape without any microscopic gaps. This technology enables sealing rings to be manufactured quickly and precisely – ensuring that they work, every time. And we can use laser welding machine portable to join them much tighter.

Using the right materials and settings is very essential to achieve the best possible seal using this technology. Laser sealing rings are composed of specialized materials that excel in high-temperature and pressure applications. That Zhilei Laser enables them to make a tight seal that won’t break, even under pressure. This process is often a laser cutting process, specifically cutting and shaping the sealing ring into its form, ensuring proper fit. With appropriate procedures and parameters, portable laser welder makes seals that are robust and stable through the time. This is what makes engineers so meticulous in the process of assembling everything.

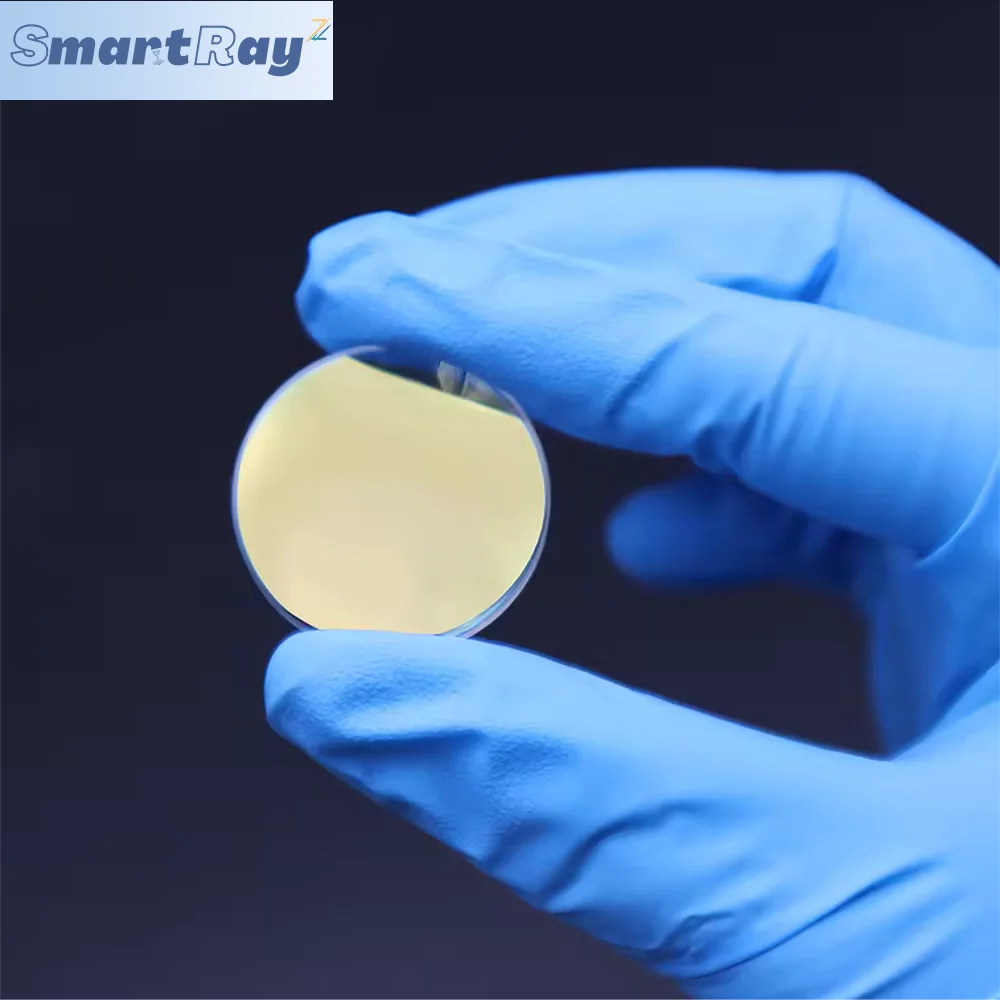

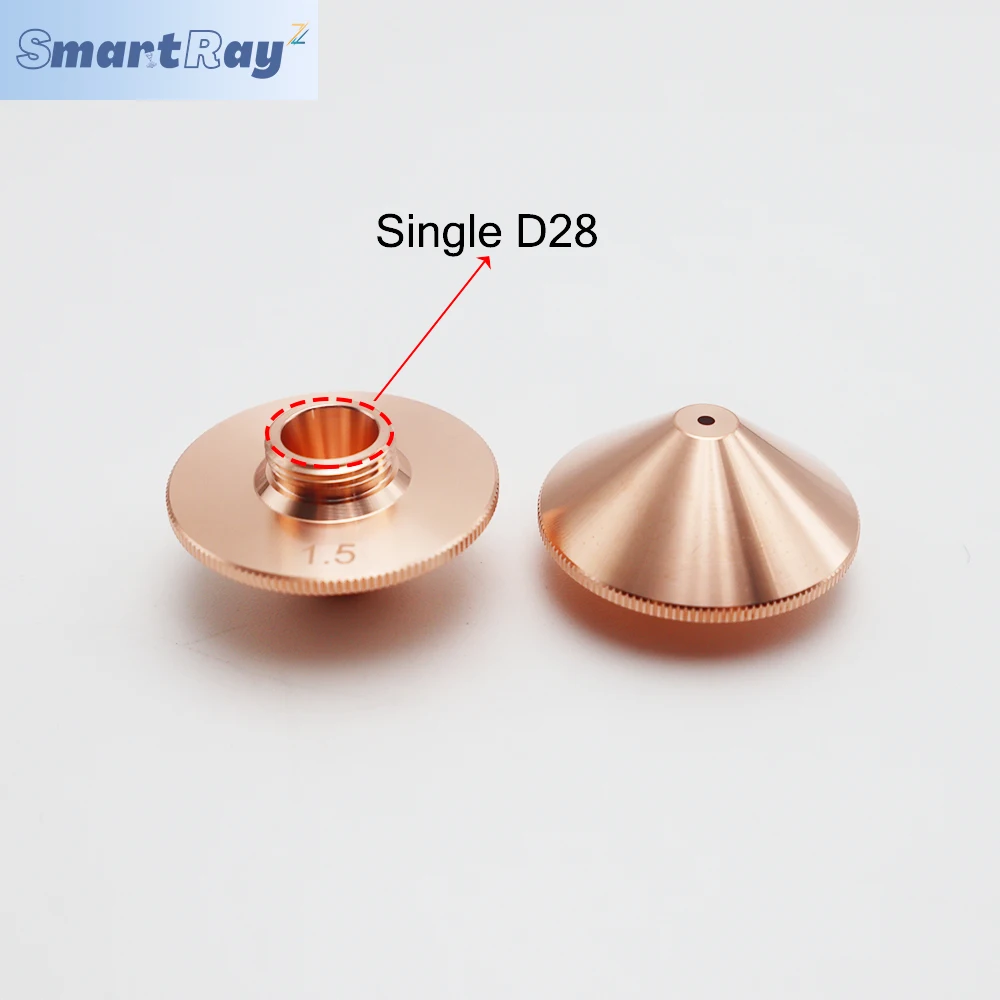

Manufacturing laser sealing rings requires a high degree of precision engineering. Therefore, every aspect has to be precisely scheduled and performed to reach a flawless outcome. This precise cutting and shaping of the sealing ring is made possible through the use of Lens laser machine, ensuring that it fits perfectly and creates a snug seal around the object. The sealing ring is meticulously designed with the best degree of precision using advanced software and tools by engineers. All of this engineering precision allows the sealing ring to work perfectly, creating a reliable seal each and every time. It is almost like putting together a puzzle where every piece has to be a perfect fit!

We're dedicated excellence and work Laser sealing ringto deliver laser products of the highest standard. Every item goes through strict testing, and each product made following strict guidelines. This ensures a reliable long-lasting performance. You can count on our products to provide an efficient and secure operation.

Our experts decades experience the industry and committed offering expert advice support. From selection products Laser sealing ring, assistance installation troubleshooting, we here assist in every step.

We your complete laser factory. We offer a variety items that will satisfy your requirements. We stock all laser parts such as Laser sealing ringheads and laser sources, chillers, and laser welding equipment you require to enhance the performance of lasers.

We know every project unique, Laser sealing ring flexible approach permits to provide customized options. Our skilled team work closely you ensure specification is tailored to meet your specific requirements.