Have you ever wondered how machines can cut through such tough things with so much ease? That may appear like magic, but there is in fact a science-based explanation behind them. A lens is one of the main components used in this step, known as laser cutting. The laser—laser is abbreviation of the Light Amplification by Stimulated Emission of Radiation—a focused and directed high-energy beam envisioned cutting through wood, plexiglass and steel as if they were hot butter; but this laser optic was no ordinary tool—the edge-forward cut to a set laser lens—for it helped focus the beams directly on target material for processing. And that is the special tool which gives them such a unique capability to do their work so well and also times very efficiently. CHEAP OEM CUT LASER LENS These lenses assist in concentrating of the laser beam thus help to make a good robust cut with high efficiency. The cut laser lens must then focus that beam and direct it to a certain spot on the material. The laser melts this material—and in some cases, even vaporizes it—at those point. This method results in a neat, crisp edge that can be used immediately. This laser lens results in very accurate cuts over a wide variety of projects.

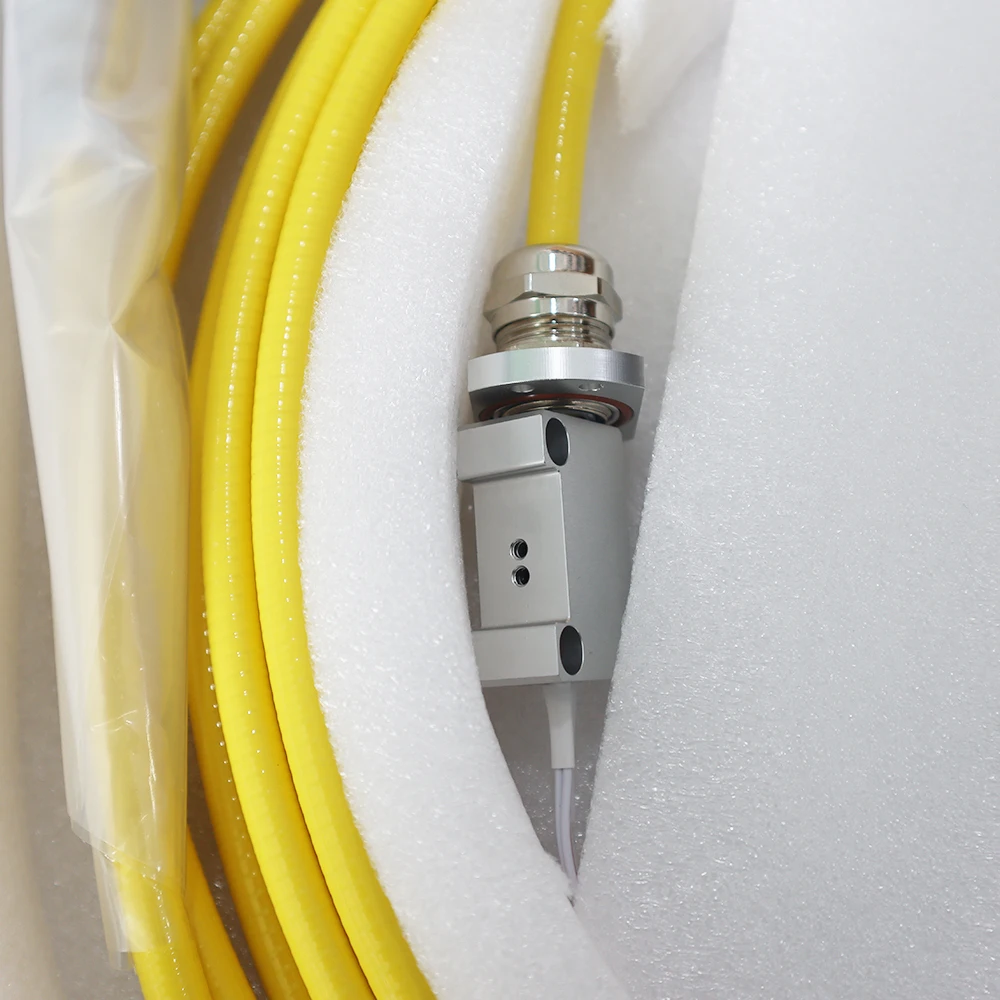

Cut laser lenses, which are made from glass, quartz or silicon. These materials are selected due to tunneling the extremely high energy of the laser beams. We are Zhilei Laser, the lenses made by our company only uses high-quality materials to guarantee that you have nothing but top. These lenses are available in various sizes, shapes and thicknesses as to laser lens focus suit the individual requirements of different machines. This is important as different cutting applications will need a specific form of lens to get the job done right. Laser lenses are integral to the functionality of a laser cutting machine, as they enable it to cut many different kinds of materials. This can involve a wide range of materials — metals such as steel and aluminum, plastics, laminates (on wood), leather or fabric coverings. A laser cutting machine can cut difference material depth by using different types of lenses This wide range of practices is one reason why so many industries rely on laser cutting.

With the right cut laser lens upgrade, your laser cutting can become stronger than ever. When it comes to changing from a marking laser lens to a cutting one, there are many benefits. Long-life laser lens : A long life, cut laser lens provides cleaner cuts, stronger edges and faster cutting times. laser protection goggles is quite a boon, especially for businesses as they save on their resources in addition to getting excellent results. When it comes to selling things, as is the case with anything in manufacturing, being efficient and creating high quality stuff makes all the difference.

Another advantage of laser cut lenses is that you can do a high-precision cutting quite simply. By narrowing the amount of laser beam and increasing its power, it offers more lens helps reduce cutting time correction As a result, you can carry out more intricate cutting jobs and produce complex shapes and designs on nonile protection laser cut want ease to cut. No matter you are working on small parts or large designs, the cut laser lenses can help to fulfil your object Click To Tweet

Laser cut lenses are a great choice as they have numerous benefits. Sustainable, resilient and of course you won't need to change them often either This not only means you save money, but also reduce disruptions to your cutting operations. Laser lenses help create smooth and accurate cuts, which in optical lens prices turn can cut down on post-process time drastically. And that makes them an excellent option for commercial and industrial manufacturing.

We your complete laser factory. We offer a variety items that will satisfy your requirements. We stock all laser parts such as Cut laser lenheads and laser sources, chillers, and laser welding equipment you require to enhance the performance of lasers.

With years industry Cut laser len Our team experts committed providing with expert advice assistance. We're here assist with everything product selection as well technical support installation tips troubleshooting.

Our drive to be the best drives us to Cut laser len laser products of top quality. Every product goes through strict testing, each product is made accordance with strict specifications. This guarantees dependable and long-lasting performance. Don't worry, you can trust top-quality products for effective and safe operation.

We that every project different, which why flexible approach permits to provide customized options. you need specific dimensions materials Cut laser len design adjustments, knowledgeable team work you tailor specification your specific needs a perfect fit your requirements.